Update 10/17/2019

Here are some useful words on cooling parameters.

It’s all about getting the right parameters. (10/9/2019)

First job, download the manual. All the relevant stuff was here. https://www.prusa3d.com/drivers/

Next, download the slicer and firmware.

Install the slicer “slic3r”

Ran treefrog I downloaded from itnernet before I realised that Prusa use the same model 🙂

Prusa reports that it needs new firmware

Thermal Runaway during printing! Better install new firmware.

Download firmware, and install manual

Connected printer USB to PC

Printed the upgrade instructions. Reference to Slic3R PE which doesn’t seem to be part of the release.

Better instructions here https://help.prusa3d.com/article/r5ByKgVm69-firmware-upgrade-and-flashing.

Although the COM port shows up, the printer needs to be switched on. Duh!

Tried again – flashing failed. Now the printer is unresponsive – no UI. It also erports that it is a Prusa 2.5 now! Did I somehow load the wrong firmware – checked… no!

< various read and write commands followed by this>

avrdude-slic3r: verifying …

avrdude-slic3r: 244050 bytes of flash verified

avrdude-slic3r: safemode: hfuse reads as D0

avrdude-slic3r: safemode: efuse reads as FD

avrdude-slic3r: safemode: Fuses OK (E:FD, H:D0, L:FF)

avrdude-slic3r done. Thank you.

avrdude-slic3r -v -p atmega2560 -c arduino -P COM16 -b 115200 -D -u -U flash:w:1:C:UserslammingDesktopPRUSAprusa3d_fw_MK3_3_8_0_2684.hex:i

avrdude-slic3r: Version 6.3-20160220-prusa3d, compiled on Sep 16 2019 at 11:15:49

Copyright (c) 2000-2005 Brian Dean, http://www.bdmicro.com/

Copyright (c) 2007-2014 Joerg Wunsch

Using Port : COM16

Using Programmer : arduino

Overriding Baud Rate : 115200

avrdude-slic3r: prusa_init_external_flash(): MK3 printer emitted incorrect start code: `echo: `

avrdude-slic3r: arduino_open(): Failed to initialize MK3 external flash programming mode

avrdude-slic3r: Could not open port: COM16

avrdude-slic3r done. Thank you.

Power cycle doesn’t cause a reboot. Should I remove USB cable?

Noticed a useful document https://help.prusa3d.com/article/gXdRubco3u-firmware-updating-flashing-problems

Contacted David to see if this is a 3Mk3. No!! It’s a 2.5S

[13:50, 10/8/2019] Mik Lamming: R u available to consult?

Is this a i3 mk3?

[13:54, 10/8/2019] David Carkeek: Sure! It’s an i3 Mk2.5S

[13:54, 10/8/2019] David Carkeek: The i3 has a 24V power supply, so the motors are faster and the hot bed heats better.

[13:55, 10/8/2019] David Carkeek: Also, the i3 has extruded aluminum rails so it’s sturdier.

[13:56, 10/8/2019] David Carkeek: The “S” upgrade was primarily new linear bearings.

[13:58, 10/8/2019] David Carkeek: The “2.5” upgrade was a new hot bed, magnetic surface, new PINDA probe and holder, new extruder and fan, filament sensor. This enabled some software improvements.

[14:02, 10/8/2019] Mik Lamming: OK, I’m having some minor issues. I tried to print the treefrog example. It got about 2m into the process and then stopped saying “thermal runaway”. UI dead. Had to turn off. Turned back on and it said “upgrade firmware”. That was my downfall. I thought it was a i3 Mk3 because that’s what it says on the bendy plate. Took me a while to figure out the instructions for firmware upgrades were wrong. Finally did an upgrade. Verified OK but then gave some gobledigook

[14:02, 10/8/2019] Mik Lamming: avrdude-slic3r: arduino_open(): Failed to initialize MK3 external flash programming mode

avrdude-slic3r: Could not open port: COM16

[14:03, 10/8/2019] Mik Lamming: OK, so that makes sense because it is a 2.5S

[14:03, 10/8/2019] Mik Lamming: Just tied to flash 2.5s and it failed. I’m going to reset everything and retry

[14:06, 10/8/2019] David Carkeek: There are two versions of the controller board and you need to be sure that you select the right one when you flash it. The same thing happened to me when I selected the wrong controller.

[14:06, 10/8/2019] Mik Lamming: OK – how do I identify the controller board?

[14:06, 10/8/2019] David Carkeek: The thermal runaway error happens with the new fan because the extruder cools down too much when it turns on and doesn’t have time to recover before the thermal runaway error kicks in.

[14:07, 10/8/2019] David Carkeek: Then newer firmware was supposed to partially fix the thermal runaway error by not requiring a ramp speed as fast as what was used before.

[14:08, 10/8/2019] David Carkeek: But I could never get it to work with the fan speed set at 100%.

[14:08, 10/8/2019] Mik Lamming: Do I need the Mk2.5 or the Mk2.5S firmware

[14:08, 10/8/2019] David Carkeek: 2.5S

[14:09, 10/8/2019] David Carkeek: There are two solutions for the thermal runaway problem. One is to put a silicone sock on the outside of the extruder.

[14:09, 10/8/2019] David Carkeek: The other solution is to set the fan speed at something like 70%. To do that do you have to edit the G-Code.

[14:10, 10/8/2019] Mik Lamming: OK – good info.

[14:10, 10/8/2019] David Carkeek: If y ou are making a new model there is an option to set the maximum fan speed in the slicer.

[14:10, 10/8/2019] Mik Lamming: There are dire warnings about not installing wrong firmware!! I wonder if I have done something dire.

[14:11, 10/8/2019] David Carkeek: For the question about the controller, I have to look. it’s obvious when you know what to look for and when it happened to me I was just careless and didn’t pay attention.

[14:11, 10/8/2019] David Carkeek: when it happened to me, I was sure that I had bricked to controller, but it seems to be pretty resilient and it was still okay.

[14:14, 10/8/2019] Mik Lamming: There is a document that shows the controller types.

[14:14, 10/8/2019] David Carkeek: I just downloaded the firmware to take a look it’s the RAMBo13A that you want.

[14:16, 10/8/2019] David Carkeek: there are versions for different languages. English is part of all of them, so it doesn’t matter which one you choose.

[14:17, 10/8/2019] Mik Lamming: Well anticipated! ?

[14:19, 10/8/2019] Mik Lamming: Flashing the French version… ?

[14:29, 10/8/2019] Mik Lamming: I guess it flashed, but is this message OK?

[14:30, 10/8/2019] Mik Lamming: Now I’m going to try and print the treefrog example again. So two questions: Which of these is the right device to choose

[14:30, 10/8/2019] Mik Lamming: And do you hand-edit the gcode to turn down the fan speed, or is there some control somewhere?

[14:33, 10/8/2019] David Carkeek: If you’re in Slic3r there’s a setting.

[14:33, 10/8/2019] Mik Lamming: I am

[14:35, 10/8/2019] David Carkeek: I’m going to have to install the program to look at it because I can’t remember enough details to explain how to get there.

[14:36, 10/8/2019] David Carkeek: Did you install 2.2.8?

[14:36, 10/8/2019] Mik Lamming: No, no! I’ll figure it out. Just want to be sure I have the right controller specified. See aboce. There are lots of different 2.5S models

[14:37, 10/8/2019] Mik Lamming: 2.2.8 Slic3r

[14:37, 10/8/2019] David Carkeek: You have the right one selected.

[14:38, 10/8/2019] David Carkeek: All those other ones are if you have the multi-material unit installed.

[14:38, 10/8/2019] Mik Lamming: Ohhhhh! Duh. OK.

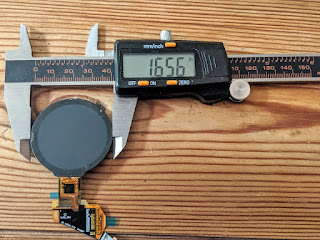

[14:42, 10/8/2019] Mik Lamming: Oh – what size noxel is fitted?

[14:43, 10/8/2019] Mik Lamming: nozzle

[14:51, 10/8/2019] Mik Lamming: This look right

[14:57, 10/8/2019] David Carkeek: It’s the standard nozzle. Maybe 0.25?

[14:57, 10/8/2019] Mik Lamming: OK thanks.

[15:00, 10/8/2019] David Carkeek: Maybe 0.4?

[15:00, 10/8/2019] David Carkeek: Probably 0.4mm

[15:01, 10/8/2019] Mik Lamming: I wonder if the hole looks like 0.4mm

[15:01, 10/8/2019] David Carkeek: Yes, it’s 0.4

[15:02, 10/8/2019] David Carkeek: I’m sure it would if it was clean.

[15:02, 10/8/2019] Mik Lamming: Oh thanks. That’s great. Did you try smaller nozzles at all?

[15:02, 10/8/2019] David Carkeek: Only the standard 0.4mm

[15:03, 10/8/2019] David Carkeek: It would be good to try others, probably.

[15:03, 10/8/2019] Mik Lamming: The watch case looked pretty good at 0.4

[15:39, 10/8/2019] Mik Lamming: I set the min and max fan speed to 70%

Flash it right!

avrdude-slic3r -v -p atmega2560 -c wiring -P COM16 -b 115200 -D -U flash:w:0:C:UserslammingDesktopPRUSAprusa3d_fw_MK25S_3_8_0_2684_RAMBo13a_en-fr.hex:i

avrdude-slic3r: Version 6.3-20160220-prusa3d, compiled on Sep 16 2019 at 11:15:49

Copyright (c) 2000-2005 Brian Dean, http://www.bdmicro.com/

Copyright (c) 2007-2014 Joerg Wunsch

Using Port : COM16

Using Programmer : wiring

Overriding Baud Rate : 115200

AVR Part : ATmega2560

Chip Erase delay : 9000 us

PAGEL : PD7

BS2 : PA0

RESET disposition : dedicated

RETRY pulse : SCK

serial program mode : yes

parallel program mode : yes

Timeout : 200

StabDelay : 100

CmdexeDelay : 25

SyncLoops : 32

ByteDelay : 0

PollIndex : 3

PollValue : 0x53

Memory Detail :

Block Poll Page Polled

Memory Type Mode Delay Size Indx Paged Size Size #Pages MinW MaxW ReadBack

———– —- —– —– —- —— —— —- —— —– —– ———

eeprom 65 10 8 0 no 4096 8 0 9000 9000 0x00 0x00

flash 65 10 256 0 yes 262144 256 1024 4500 4500 0x00 0x00

lfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

hfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

efuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

lock 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

calibration 0 0 0 0 no 1 0 0 0 0 0x00 0x00

signature 0 0 0 0 no 3 0 0 0 0 0x00 0x00

Programmer Type : Wiring

Description : Wiring

Programmer Model: AVRISP

Hardware Version: 15

Firmware Version Master : 2.10

Vtarget : 0.0 V

SCK period : 0.1 us

avrdude-slic3r: AVR device initialized and ready to accept instructions

Reading | ################################################## | 100% 0.01s

avrdude-slic3r: Device signature = 0x1e9801 (probably m2560)

avrdude-slic3r: safemode: hfuse reads as D0

avrdude-slic3r: safemode: efuse reads as FD

avrdude-slic3r: reading input file “C:UserslammingDesktopPRUSAprusa3d_fw_MK25S_3_8_0_2684_RAMBo13a_en-fr.hex”

avrdude-slic3r: writing flash (218614 bytes):

avrdude-slic3r: stk500v2_command(): command failed

Writing | ################################################## | 100% 41.06s

avrdude-slic3r: 218614 bytes of flash written

avrdude-slic3r: verifying flash memory against C:UserslammingDesktopPRUSAprusa3d_fw_MK25S_3_8_0_2684_RAMBo13a_en-fr.hex:

avrdude-slic3r: load data flash data from input file C:UserslammingDesktopPRUSAprusa3d_fw_MK25S_3_8_0_2684_RAMBo13a_en-fr.hex:

avrdude-slic3r: input file C:UserslammingDesktopPRUSAprusa3d_fw_MK25S_3_8_0_2684_RAMBo13a_en-fr.hex contains 218614 bytes

avrdude-slic3r: reading on-chip flash data:

Reading | ################################################## | 100% 27.98s

avrdude-slic3r: verifying …

avrdude-slic3r: 218614 bytes of flash verified

avrdude-slic3r: safemode: hfuse reads as D0

avrdude-slic3r: safemode: efuse reads as FD

avrdude-slic3r: safemode: Fuses OK (E:FD, H:D0, L:FF)

avrdude-slic3r done. Thank you.

Some success

I wonder what this means?

Need to adjust fan speed to prevent thermal runaway.

——————