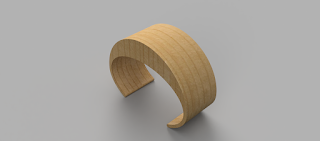

Here’s a brute force parametric model. It took me two revisions to get it up to the point where it was worth printing. It’ is indeed a crock of shit, but it highlights some of the more obvious problems. There are parameters for every dimension so it should be easy to change the cavity size, width and wall thickness etc.

The gray block in the second picture is a battery, and the green block is the DW1001. I was looking at curved batteries, but I think it perhaps makes more sense to use two smaller LiPos mounted end-on at each end of the cavity. Then I think the cavity can be a lot smaller.

I’m thinking there will be a plug that somehow pushes into the open side of the cavity. The plug could even have a couple of brass terminals for charging.

I rendered it in a wood finish because it’s easier to see the shape.

I printed the cuff and a battery model using ABS to see how it fitted.

The Good

- The model printed!

- It flexes enough that I can force it over my wrist without it snapping

- It is really snug.

- The dummy-battery, DW1001, and tickler all fit inside OK with to spare. It doesn’t look that bad, considering it’s a first attempt.

The Bad

- The battery sagged, and it’s radius changed as it printed and I had to sand it down to fit which looks nasty. but it fits.

- It’s translucent. Maybe nylon will be less so, or maybe I have to figure out how to make the translucency a feature.

- It seems clear that “one size ‘fits’ all” isn’t going to work

The Ugly

- “Snug” is an understatement.